Core contradictions, common methods, and practical suggestions for pilot scale-up

Behind these phenomena lies a systemic challenge triggered by scale effects.

As the volume of the device increases, nonlinear changes occur in physical fields, transfer processes, and cellular microenvironments.

The core contradiction in the amplification process is that traditional amplification thinking often assumes that the parameters of the large tank are simply a multiple extension of those of the small tank, ignoring the qualitative changes in system properties brought about by volume growth.

From the perspective of engineering thermodynamics and bioprocess engineering, there are primarily three core contradictions in scaling up:

1. Oxygen transfer: The efficiency of oxygen transfer (kLa) is influenced by multiple factors such as aeration rate, stirring shear force, and tank geometry.

2. The fully mixed flow distribution within different small tanks is difficult to maintain at a 2000L scale, and the stirring blind zone leads to the appearance of dead zones.

When the shear stress gradient difference increases, the risk of cell lysis increases, and the probability of protein aggregation rises.

3. The spatial limitations of different pH probes in the microenvironment lead to detection blind spots, and the accumulation of CO₂ triggers intracellular acidosis, inhibiting antibody synthesis.

These "invisible variables" have become key factors in yield fluctuations.

II. Currently commonly used amplification methods

Currently, the "multi-scale coupling + digital twin" method is commonly employed to reduce the risk of scaling up through laboratory modeling, pilot verification, and production optimization.

The specific implementation can be divided into three stages:

1. Preliminary testing phase: Construct a predictive model • Screen key process parameters (CPPs) through DOE • Measure kLa using dynamic dissolved oxygen method and plot the "kLa-scale" curve • Simulate flow field distribution using a scaled model and optimize the design of the stirring paddle

2. Pilot stage: Digital twin verification • Real-time monitoring of Raman spectroscopy, near-infrared, and other data • CFD simulation to reveal flow field distribution characteristics • Comparing virtual models with measured data to calibrate parameters

3. Production stage: Continuous process validation • Monitoring indirect indicators such as cell apoptosis rate and glycosylation modification • Iterative updating of the knowledge base to support larger-scale production

III. Practical Suggestions During the pilot stage, it is recommended to incorporate scalability assessment, prioritizing the determination of core parameters such as kLa, mixing time, and shear force.

Before the pilot test, it is advisable to consider using Computational Fluid Dynamics (CFD) to construct a flow field model, with a focus on the proportion of dead zones and the distribution of shear forces.

Finally, gradually establish a scale effect database to record the parameter variation patterns under different scales.

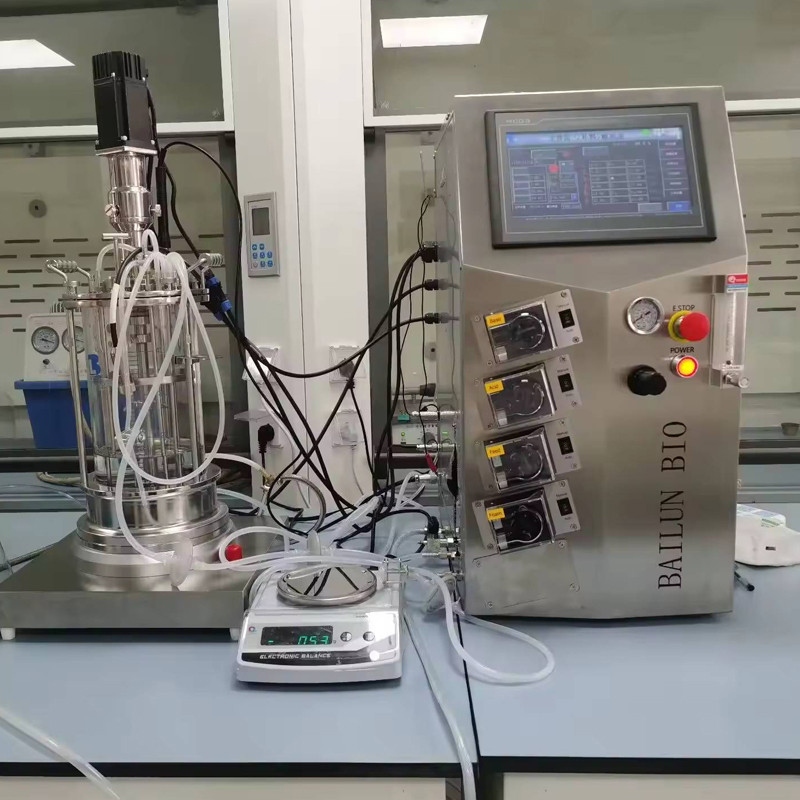

Bailun Biotech has long been deeply engaged in the research and development of bioreactor equipment and core components. The company has accumulated profound technical expertise in areas such as mass transfer efficiency optimization and component structural design.

Through independent research and development, it has secured multiple core technology patents. Its bioreactor-related components have been widely applied in fields such as biomedicine and microbial fermentation.