Fermentation experiment - Effect of different stirring combinations on the production performance of L-threonine

Select different stirring combinations for fermentation experiments of Escherichia coli producing L-threonine, study the fermentation performance of L-threonine under different stirring combinations from a physiological perspective, and explore suitable stirring combinations for L-threonine fermentation production.

1、 Experimental purpose

Through E. coli fermentation experiments, verify the effect of the stirring combination screened by CFD simulation on the production performance of L-threonine, and optimize the fermentation process parameters.

2、 Experimental principle

By comparing the bacterial concentration, glucose consumption rate, and amino nitrogen accumulation under different stirring combinations, the influence of the stirring system on mass transfer efficiency is evaluated, and the optimal stirring scheme is verified by combining CFD simulation results.

3、 Experimental Materials and Methods

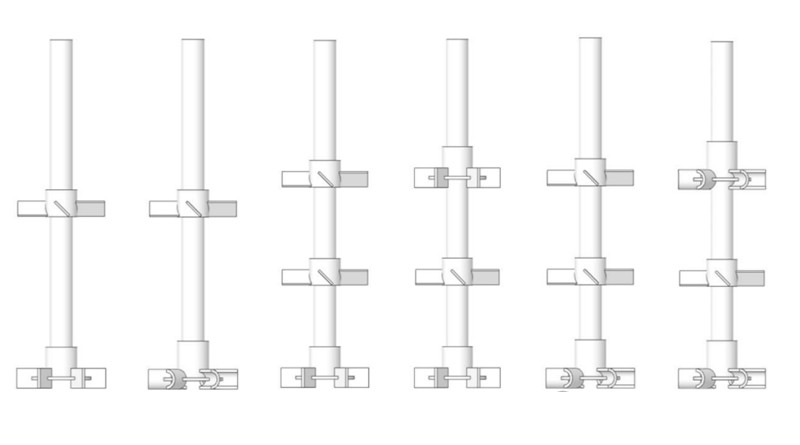

Fermentation tank specification: 30L Bailun biological stainless steel tank with 4 baffles, built-in three-layer mixing combination auxiliary equipment: sterilization pot, shaker, centrifuge, biosensing analyzer, etc

cultivation process

Strain activation: inclined cultivation for 24 hours (37 ℃) Seed cultivation: shaker cultivation for 6 hours (200rpm, 37 ℃) → seed tank cultivation for 7 hours

Fermentation cultivation

Initial conditions: Ventilation rate of 0.6m ³/h, rotation speed of 200rpm, temperature of 37 ℃, pH 7.0. Control strategy: Dissolved oxygen of 2550%, feed in when residual sugar is less than 10g/L

Detection method

Bacterial concentration: OD562nm spectrophotometric method

Glucose concentration: Biosensing analyzer method Amino nitrogen concentration: Formaldehyde titration method (formula: Amino nitrogen (mg/100mL)=C × V × 14.01 × 100/2.5)

4、 Experimental results and analysis

The OD value of combination F at 1640h was significantly higher than that of other groups (p<0.05), indicating that its flow field is more conducive to bacterial proliferation.

Combination F had the lowest glucose concentration at 24 hours (6.8g/L), which was 35% lower than the control group.

At 48 hours, the concentration of amino nitrogen in combination F reached 185g/L, an increase of 42% compared to the control group.

5、 Conclusion

The optimal mixing scheme is the three-layer radial flow combination F (upper two layers of six semi-circular turbine blades+lower four inclined straight blade blades).

The experimental results are highly consistent with the CFD simulation, verifying the reliability of the simulation method.

This stirring system can increase the production of L-threonine by more than 40% and has industrial application value.