The secret to producing ten thousand tons annually! 10 Research and Practice Directions for Process Control for "Advanced Fermentation Engineers"!

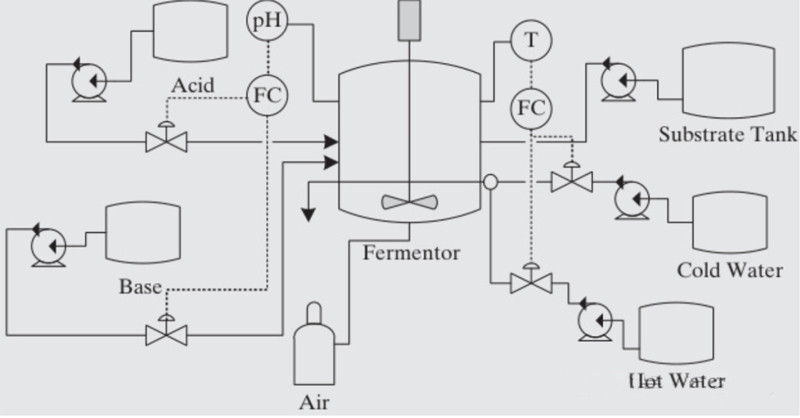

1. Closed loop control based on dynamic parameters:

Based on real-time monitoring of metabolic parameters such as dissolved oxygen, pH, and substrate concentration, the stirring, aeration, or feeding rates are dynamically adjusted through feedback algorithms to maintain the steady state of bacterial metabolism.

2. Optimization of phased replenishment strategy:

According to the microbial growth curve (lag phase, logarithmic phase, stable phase), carbon and nitrogen sources are supplemented in stages to balance the resource allocation of bacterial growth and product synthesis.

3. Gradient optimization based on dissolved oxygen:

By adjusting the stirring power and ventilation rate, the dissolved oxygen concentration gradient is controlled to match the oxygen requirements of different metabolic stages (such as low dissolved oxygen required in the later stages of antibiotic fermentation).

4. Enzyme activity control based on temperature coupling:

According to the kinetic characteristics of key enzymes synthesized from the target product, adjust the temperature in stages (such as prolonging enzyme stability at low temperatures and accelerating cell growth at high temperatures).

5. Research on pH Metabolism Interaction Balance:

Maintain pH within the optimal range of enzyme activity and membrane permeability through automatic acid-base supplementation, avoiding feedback inhibition of metabolic byproducts such as organic acids.

6. Targeted control based on metabolic diversion:

Utilize nutritional restrictions (such as phosphate starvation) or inducers (such as IPTG) to close competitive metabolic pathways and enhance target product flux.

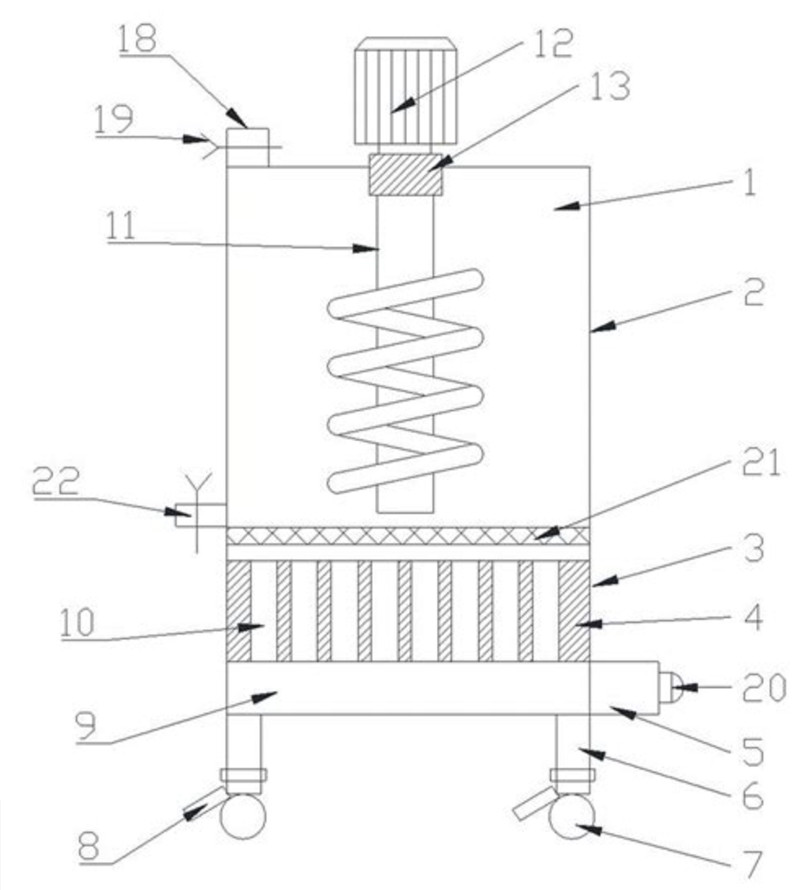

7. Resolution mechanism based on foam synergy:

Combined with mechanical defoamer (physical defoamer) and silicone defoamer (chemical foam inhibitor), the effect of foam on gas mass transfer and bacterial infection probability is reduced.

8. Maintenance of genetic robustness of bacterial strains:

By dynamically adjusting selection pressure (such as antibiotic concentration gradients) or plasmid stability elements, gene loss or mutation can be prevented during continuous passage.

9. Multi source sensor data fusion:

Integrate online Raman spectroscopy, exhaust gas mass spectrometry, and electrochemical sensor data to construct a metabolic flux model for cross scale accurate prediction.

Are bacteria selling at sky high prices? These 8 patented strains support the trillion dollar pharmaceutical market. What does the more expensive "bio chip" look like?

10. Design of sterile boundary system:

Adopting a two-stage air filter (0.2 μ m), in situ sterilization (SIP), and positive pressure tank control, multiple barriers are established to suppress the risk of bacterial contamination.